Measuring Wine Astringency Using Gelatin

Timothy Winey

Thursday, May 2, 2024

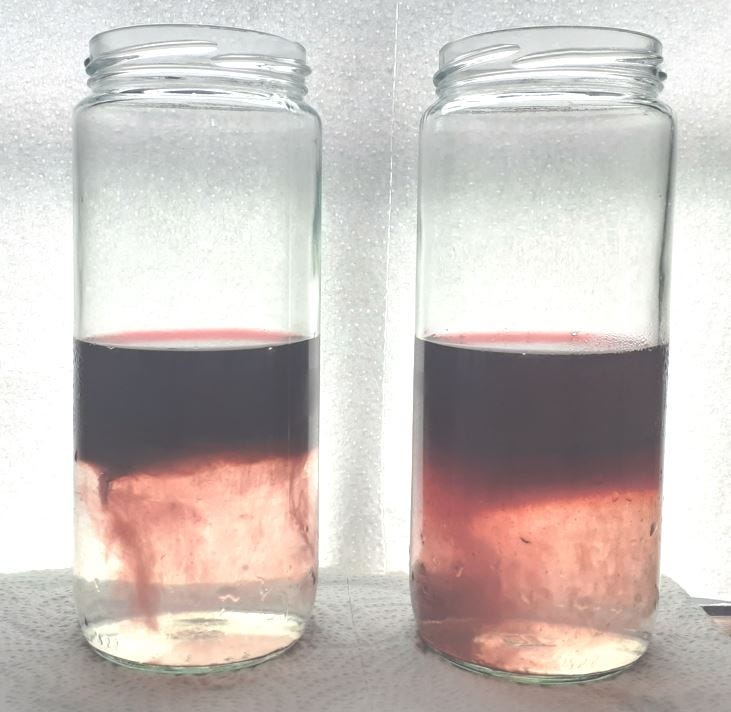

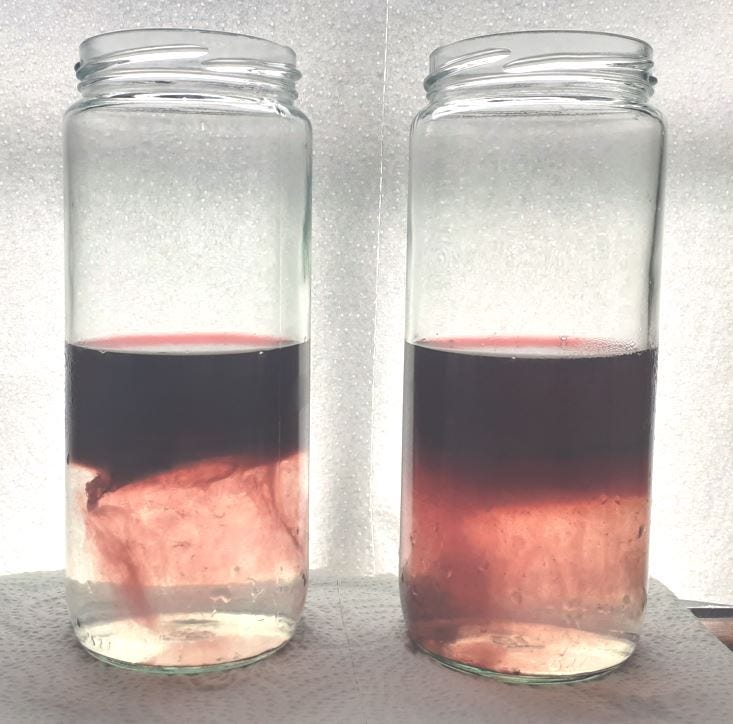

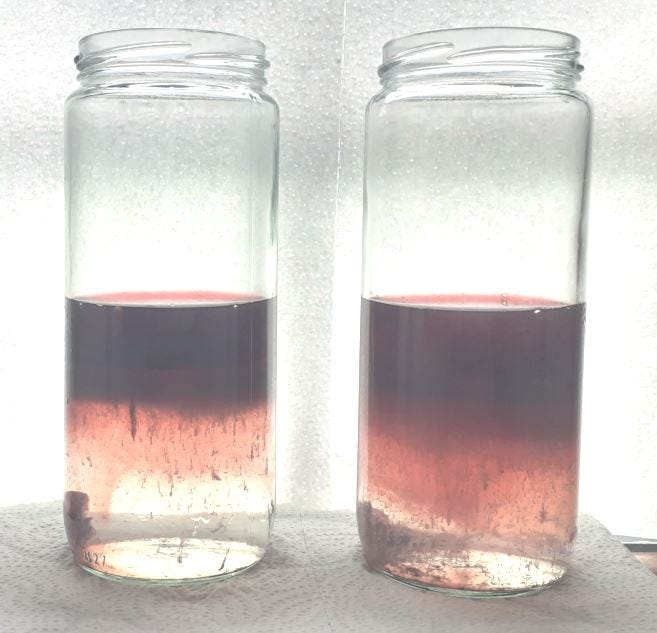

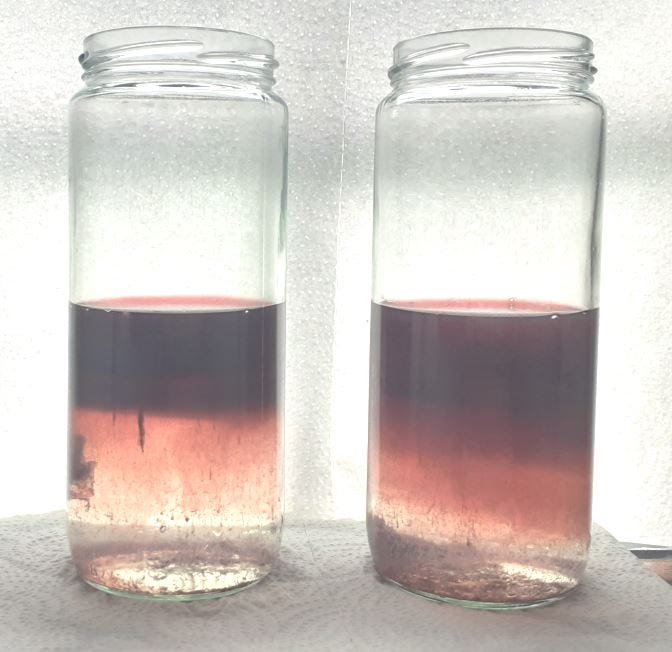

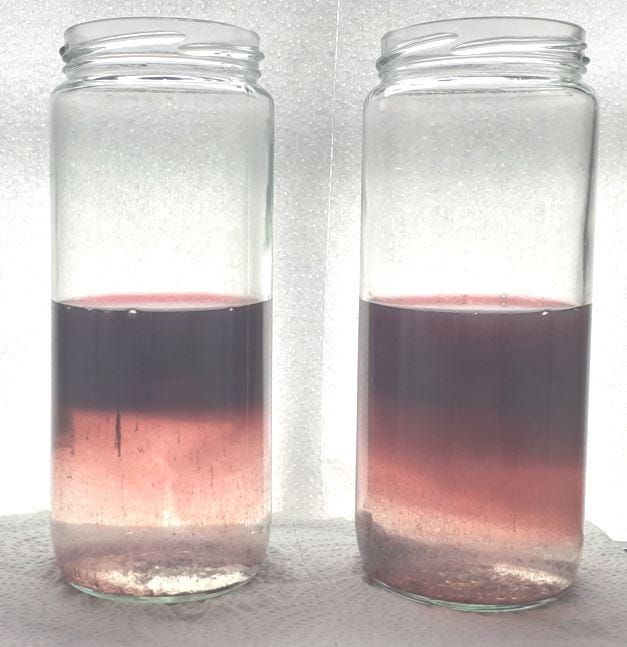

A dense preparation of clear gelatin was split into two samples. Then a sample of inexpensive astringent red wine was split into two equal samples with one exposed to a torsion field for 15 minutes after which both wine samples were poured over the gelatin samples and left to react. Owing to the density of the gelatin preparations and the slow reaction rate, both jars were placed briefly in a heat bath to initiate the breakdown of the gelatin. Once removed from the heat bath, both samples were photographed at varying intervals. Note the more extensive breakdown of gelatin in the control jar (right) compared to the torsion-exposed jar (left). Gelatin may prove a cheap and convenient means of measuring astringency of red wine as well as any attempts to modify it.

After 4 hours:

Astringency in wine is primarily attributed to compounds like tannins, which bind to proteins in the mouth, causing a dry, puckering sensation. Gelatin, being a protein-based substance, could potentially interact with these tannins in a similar manner.

One approach could involve creating gelatin gels with standardized concentrations and measuring their firmness or texture before and after exposure to different wines. The degree of softening or change in texture could then be correlated with the astringency level of the wines tested.

However, there are several factors to consider:

Standardization: Ensuring consistency in gelatin concentration and preparation is crucial for accurate measurements.

Interference: Other compounds present in wine, such as acids and sugars, could also affect the gelatin's texture, potentially complicating the measurement of astringency.

Subjectivity: Astringency perception can vary among individuals, so establishing a standardized method of measurement is essential for reliable results.

Comparative Analysis: It would be necessary to compare the results obtained from gelatin with established methods of measuring wine astringency, such as sensory evaluation or chemical analysis, to validate the effectiveness of the approach.

In conclusion, while gelatin could potentially serve as a platform to measure wine astringency, further research and validation would be needed to determine its reliability and accuracy compared to existing methods.

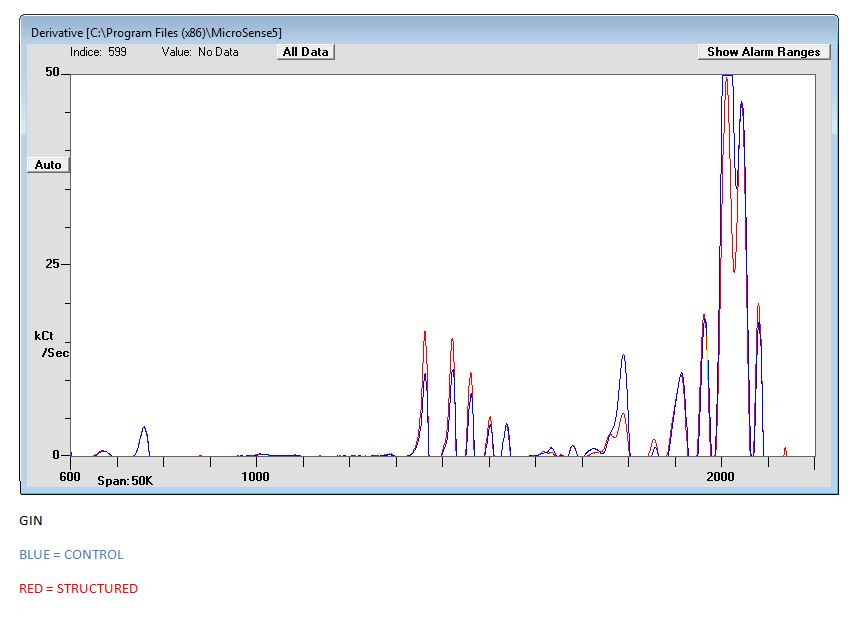

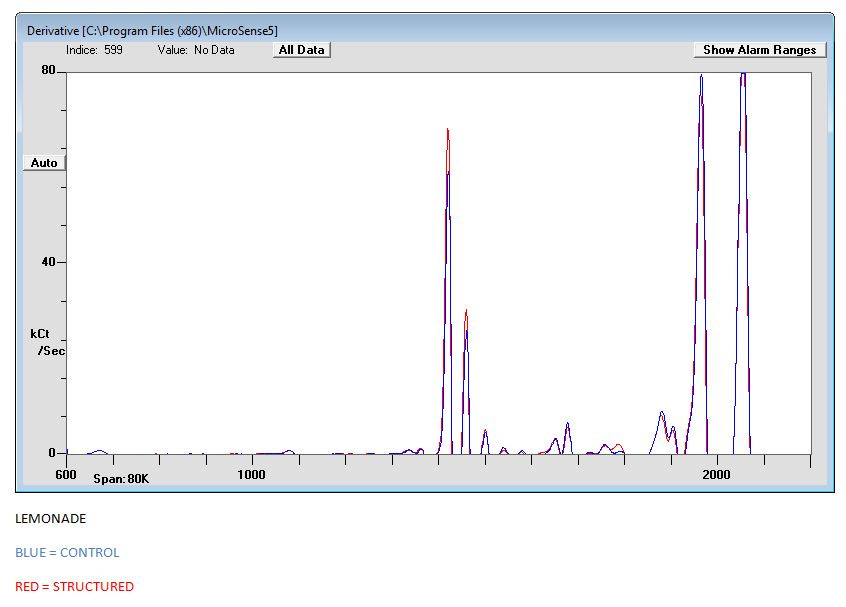

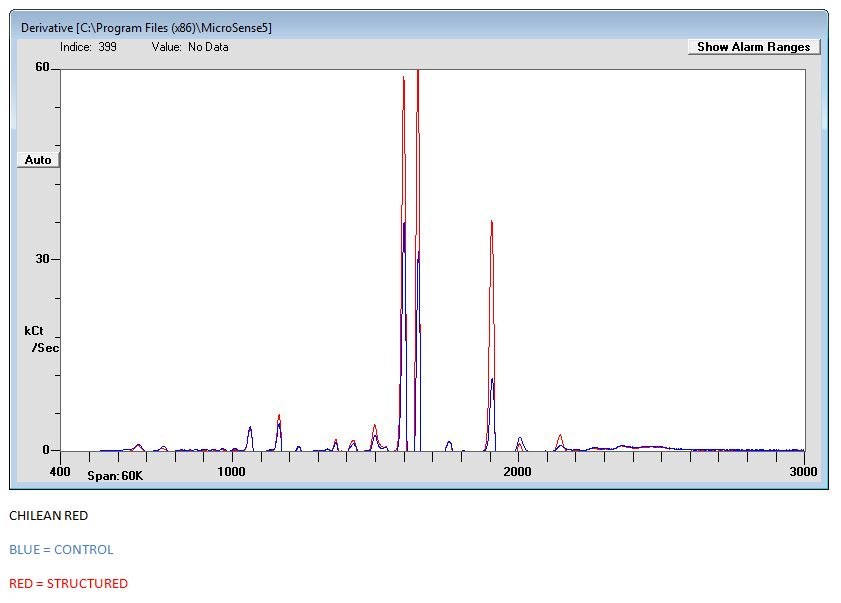

Below are some scans conducted at Northumbria University of different torsion field-exposed liquids using the zNose mass spectrometer.

Near Real Time Testing of Wine Headspace Vapors for TCA using an Ultra- High Speed Gas Chromatograph, the zNoseâ

Electronic Sensor Technology, 1100 Business Center Circle, Newbury Park, California

Summary

Headspace vapors from four different wine samples were tested for the presence of TCA using an ultra-fast gas chromatograph called the zNoseÔ. The zNose system consists of a vapor preconcentrator, a direct-heated high-speed chromatography column, a solid-state non-specific sensor, and a programmable gate array microprocessor. Twenty milliliters of each wine was placed in a septa-sealed 40 milliliter vials and the chemistry of the headspace vapors from each sample analyzed for the presence of TCA. Trace amounts of TCA (picogram levels) were detected in the headspace vapors from two of the wine samples.

Introduction

Chemical sensor arrays, called eNoses, have interested wine producers for some time, yet physical sensors have limited performance because of overlapping responses and physical instability. However, using ultra-high speed gas chromatography, a different kind of electronic nose has been achieved. With chromatography, arrays of virtual chemical sensors with non-overlapping response are possible. Long term stability coupled with picogram sensitivity enables quantification and recognition of many different chemicals in wine. Virtual chemical sensors combined with aroma profiling can be an effective method for real time quality control.

Description of the zNoseâ

A portable zNose™ used to test wine samples is shown in Figure 1. The high performance of the vapor analyzer is achieved by using a new type of solid-state GC detector with picogram sensitivity and a directly heated capillary column capable of programmed temperature ramping at rates as high as 20oC/second. A typical chromatographic analysis of a wine aroma spans only 10 seconds and measurements can be easily repeated at 1-minute intervals.

Figure 1- Portable zNose™ vapor analyzer

Using only resonant sound waves, the solid-state sensing element provides sensitivity comparable to an electron capture detector yet is non-ionic and non-specific enabling it to detect all organics regardless of polarity. Radioactive element or high voltage ionization sources are not used. The ability to detect compounds universally enables the zNoseâ to characterize a wide range of aromas and chemical vapors associated with wines and wine production methods.

N-Alkane Standard Response and TCA Calibration

An aroma standard or perfume of n-alkanes is used to calibrate retention time and specificity of the electronic nose. Specificity is what allows the instrument to recognize known chemicals and/or chemical groups (odor signatures) and to deliver the appropriate alarms. The GC can separate and measure the concentration of the individual chemicals, such as trichloroanisole (TCA), typically in 10 seconds as shown in figure 2. Individual chemicals are recognized by their retention time relative to the retention times of linear chain alkanes e.g. Kovats indices. TCA has an index of 1331 which is confirmed by overlaying the n-alkane response shown in red.

Figure 2- TCA response relative to n-alkanes (in red) using 10oC/second temperature ramp

Resolving power or the ability to separate different chemicals is proportional to the square root of column length. Although columns for the zNoseâ can be as long as 5- meters, wine samples in this case were tested using a 1-meter column. Although a 1- meter column has approximately 1/3 the resolving power of a 10-meter column there was no difficulty separating the TCA from the principal components of the wines tested. Lowering the temperature ramp rate and increasing the analysis time can also increase resolving power. For testing wine samples the temperature ramp rate was lowered to 3oC/sec and the system response using a 1.7 nanogram injection of TCA is shown in Figure 3.

Figure 3- TCA response relative to n-alkanes (in red) using 3oC/second temperature ramp

Wine No. 1 Testing Results

Chromatogram results obtained from sampling the headspace vapors from wine sample no. 1 is shown in figure 4.

Figure 4- Chromatogram obtained by sampling headspace vapors from wine sample no. 1. Expanded chromatogram shows TCA was not detected.

Wine No. 2 Testing Results

Approximately 4 picograms of TCA was detected in this wine sample.

Figure 5- Expanded chromatogram obtained by sampling headspace vapors from wine sample no.2 showing 3.4 pg TCA detected.

Wine No. 3 Testing Results

Approximately 17 picograms of TCA was detected in this wine sample.

Figure 6- Expanded chromatogram obtained by sampling headspace vapors from wine sample no.3 showing 17.3 pg TCA detected

Wine No. 4 Testing Results

No TCA was detected in headspace vapors from this sample.

Figure 7- Expanded chromatogram obtained by sampling headspace vapors from wine sample no.4 showing no TCA detected

Summary

TCA detection using direct sampling of headspace vapors from wine samples was demonstrated using an electronic nose based upon fast chromatography. Detecting trace levels of TCA in wine vapors with a non-specific detector is made difficult due to the presence of other volatile organics whose ppm concentrations can be over a million times higher than the ppt concentration of TCA. Nevertheless in two of the wine samples picogram levels of TCA was detected. The actual concentration of TCA in the samples was not known and no effort was made to assess source levels or recovery of the method. The ability to detect TCA in this case clearly demonstrated the sensitivity and large dynamic range of the instrument. Improved extraction methods such as high flow sparging or SPME absorption would increase the reliability and sensitivity of testing the wine for TCA.

The zNose is a good tool for assessing wine production methods and quality control. In addition to finished wine it could be put to good use in testing quality of wine barrels and containers such as bottles and other containment vessels. The ability to perform literally hundreds of chromatographic analyses per day represents a substantial cost savings compared to conventional long-column GC testing which is slow and certainly not portable. With the zNose virtually any part of the winery and its production processes can be subjected to analytical testing in near real time.

References:

1.

2. https://www.sjsu.edu/faculty/watkins/turin.htm

3. https://www.researchgate.net/publication/266143714_Stinky_Armpit_Wine

http://www.znose.jp/samplePDF/AromaChemistryWineBarrels.pdf